Awọn ọja

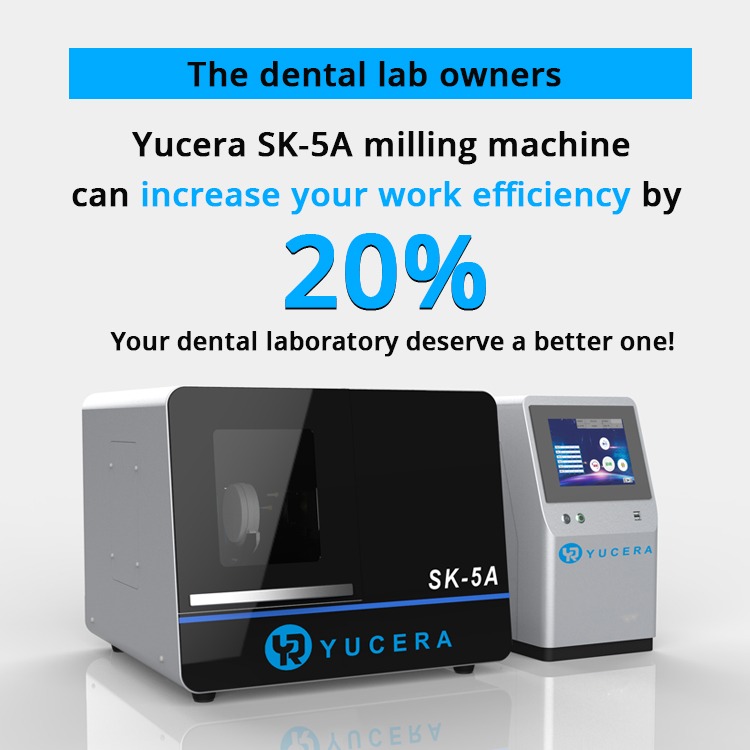

Yucera SK-5A 5axis Dental Milling Machine Cad Cam Dental Zirconia Dina deede giga.

Apejuwe ọja

1.iwuwo

Mainengine:20KG

2.Rotating axis ṣiṣẹ igun

A:360°

B:±30°

3.Apapọ agbara: 800W

4.Cutting konge: 0.02mm

5.Tool irohin agbara: 5

6.Burs ni pato Awọn atilẹyin pataki fun mimu iwọn 4mm

7.Processingmethods: Marun-axis linkage, gbẹ milling

9.Mainaxis iyara: 0-60,000rmp

10.Stable foliteji: 220-230V

Awọn ohun elo 11.Milling: Awọn bulọọki Zirconia, PMMA, Wax, Ohun elo Apapo

Itọju ohun elo

1.Regular Cleaning: Lo ohun elo omi ti o yẹ lati nu apakan ṣiṣu, ki o si ṣọra ki o maṣe lo ibon afẹfẹ lati nu inu ilohunsoke lati ṣe idiwọ eruku ati idoti lati titẹ awọn ẹya ẹrọ.

2.Materialfixturecleaning: Awọn didi ati awọn skru yẹ ki o wa ni mimọ nigbati o ba gbe ohun elo fun imudani to dara julọ

3.Main Axis Clip Cleaning: Maṣe fun sokiri epo tabi afẹfẹ fisinuirindigbindigbin ti o ni epo ati omi taara lori ori ọpa;Awọn spindle Chuck ati bur gbọdọ jẹ clean.The titẹsi ti impurities le fa processing ikuna.

1.Split typemachine;rọrun lati ṣetọju, dinku ibajẹ ti eruku si ẹrọ akọkọ, ati gigun igbesi aye iṣẹ ẹrọ naa

2.Horizontalmachine, aarin kekere ti walẹ, iduroṣinṣin to lagbara;Iyara sisẹ pọ nipasẹ 20%

3.Imudara imuduro, iwọn lilo ti bulọọki zirconium ti pọ si nipasẹ 30%;Awọn ẹya 38-48 ti ade / Afara le ge ni akoko kan