Products

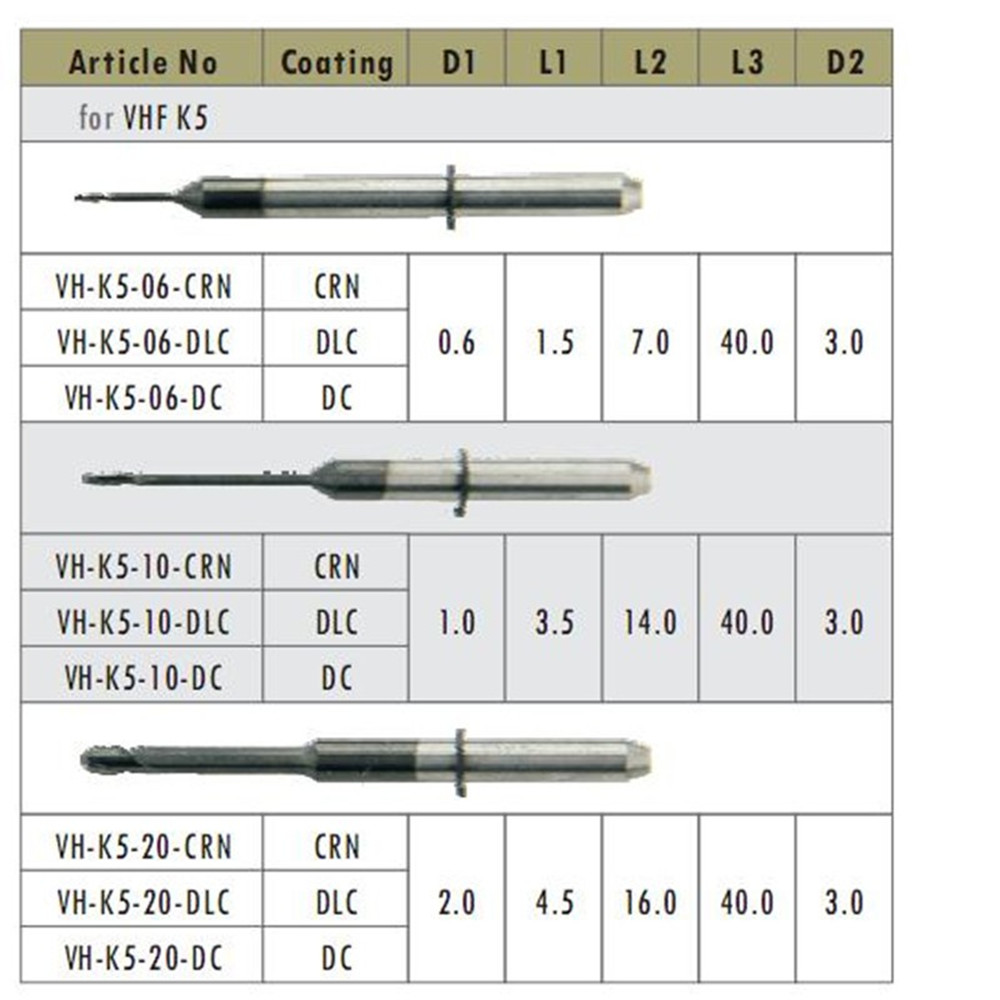

VHF milling burs K5 0,3 / 0,6 / 1,0/2,0mm for CAD CAM VHF milling machine for diamond boron milling

VHF milling burs K5 0,3 / 0,6 / 1,0/2,0mm for CAD CAM VHF milling machine for diamond boron milling

|

Model |

Head Diamater |

Strength |

Shank Diamater |

|

VHF |

0.6 |

35/40 |

3 |

|

1.0 |

35/40 |

3 |

|

|

2.0 |

35/40 |

3 |

|

|

2.5 |

35/40 |

3 |

|

|

Wieland |

0.6 |

35/40 |

3 |

|

1.0 |

35/40 |

3 |

|

|

2.5 |

35/40 |

3 |

|

|

Zirkon zahn |

1.0 |

57 |

3 |

|

2.0 |

57 |

3 |

|

|

Amann Girrbach |

0.6 |

47 |

3 |

|

1.0 |

47 |

3 |

|

|

2.5 |

47 |

3 |

|

|

Roland |

1.0 |

57 |

3 |

|

2.0 |

57 |

3 |

Size: VHF milling burs 0.6/1.0/2.0mm

1. 100% compatible with VHF cadcam milling machine

2. High quality burs,Titanium coated. it can drill 80 to 90 units teeth.

3. dental spec, shank diameter is 3.0mm. Head diameter is (Size 0.6/1.0/2.0mm);Length is 35mm.

4. You can choose each size you need.

VHF Milling Bur Characteristics:

1. DLC coating mlling tool can mill 120 to 150 units teeth.

2. DC coating milling tool can mill 300-500 units teeth.

3. All our burs are made by the optimal tungsten carbide material and stainless steel

[Product Feature:]

DLC coated, this is the most commonly used type, it can be used on zirconium and wax .

as our experience, one DLC bur assembled on Dentium system to mill Upcerama block can finish 90 to 130 teeth

DC coated, it is the most durable type, special for zirconium. it is not suitable for PMMA or WAX .with DC Coating , the life is 7 to 10 times than DLC layer. it can mill 800 to 1100 teeths.

CrN coated, special for PMMA and WAX, its cutting surface usually come out very smooth

Used for coarse abrasion on gold and other precious metals , leaving a smooth surface on acrylics. This reduces rework