Cov khoom

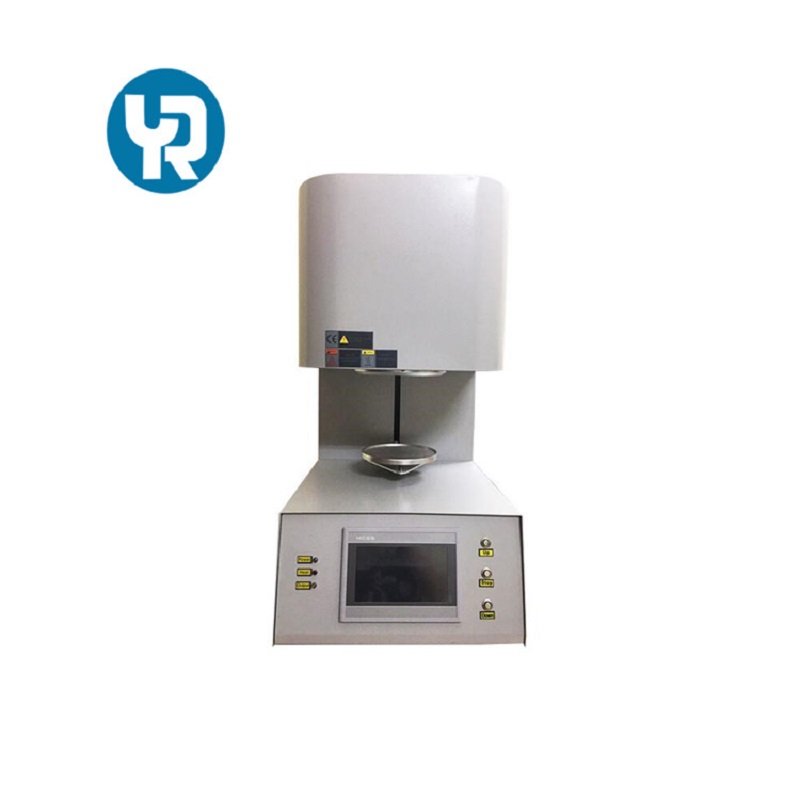

Hniav sintering rauv Nqus zir rauv rau kev kho hniav cov khoom siv-dental lab sintering rauv

Hniav sintering rauv Nqus zir rauv rau cov khoom siv kho hniav - Kev kho hniav mini sintering rauv

Cov ncauj lus kom ntxaws khoom piav qhia ntawm kev kho hniav sintering rauv:

| Lub npe | Chav tsev | Parameter |

| Lub zog ua haujlwm | KW | 1.5 KW TSI |

| Qhov hluav taws xob | V | AC220V, 50/60Hz, Ib theem |

| Max.Kub | ℃ | 1700 |

| Ua haujlwm kub tsis tu ncua | ℃ | 1600 |

| Pom zoo cua sov tus nqi | ℃ / min | ≤ 20 |

| Kub qhov tseeb tswj | ℃ | ± 1 |

| Cua sov ntsiab | MoSi2 rhaub | |

| Kev sib txuas ntawm cov khoom cua sov | Hauv series | |

| Thermal Khuv Xim | B hom | |

| Dimension ntawm sab hauv chamber | nti | 100 x 100 x 100 mm |

Specifications

1.Lub tshuab hluav taws xob siv lead ua tsim rau Bantering Draconian.Cov khoom siv cua sov siv lub siab purity silicon molybdenum rods, Draconian tsis muaj kuab paug, thiab muaj qhov kub thiab txias, tsis yooj yim rau deformation, qhov zoo ntawm lub neej ntev.

2.Cov khoom siv rauv ua los ntawm crystalline mull ceramic fiber yog nqus-adsorbed kom nruj me ntsis tswj cov hlau impurity cov ntsiab lus nyob rau hauv txoj kev tsim, uas muaj peev xwm ua tau raws li qhov yuav tsum tau ntawm ntau yam ceev Bantering thiab ua rau crystallization ib puag ncig ntawm Draconian ntau ntshiab.

3.Cov khoom no tau siv dav hauv cov neeg ua haujlwm hauv tsev thiab txawv teb chaws.

Kub tswj

1) Txais AI siab tshaj plaws kev txawj ntse hloov kho algorithm, tsis muaj overshoot, tuaj yeem ua tiav txoj kab nqes nce thiab poob tswj, nrog dhia (lub voj voog), khiav, nres thiab nres programmable / ua haujlwm cov lus txib.

2) Kev ntsuas qhov tseeb: 0.2 qib

3) Tswb muaj nuj nqi: lub tswb txwv sab sauv, input qhib tswb.

4) 50 ntu ntawm kev tswj hwm kev ua haujlwm