Products

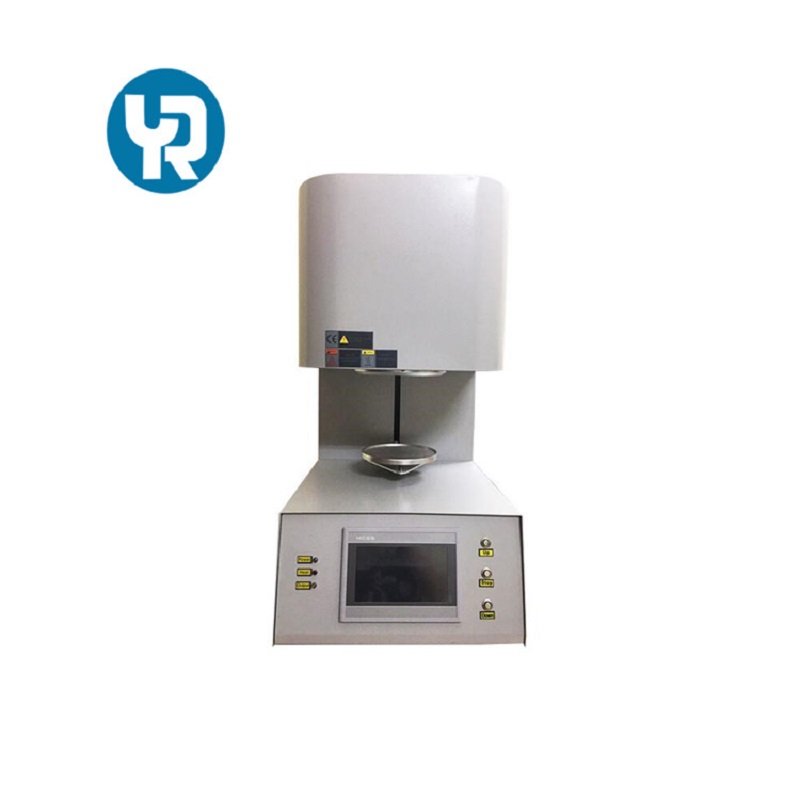

Dental sintering furnace Vacuum zir furnace for dental lab material-dental lab sintering furnace

Dental sintering furnace Vacuum zir furnace for dental lab material-dental mini sintering furnace

Detailed Product Description of dental sintering furnace:

|

Name |

Unit |

Parameter |

|

Working Power |

KW |

1.5 KW |

|

Voltage |

V |

AC220V,50/60Hz,Single phase |

|

Max. Temperature |

℃ |

1700 |

|

Continuous working temperature |

℃ |

1600 |

|

Suggested heating rate |

℃/min |

≤ 20 |

|

Temperature accuracy controlled |

℃ |

± 1 |

|

Heating element |

MoSi2 Heater |

|

|

Connection of heating element |

In series |

|

|

Thermal Couples |

B type |

|

|

Dimension of inside chamber |

inch |

100x100x100mm |

Specifications

1.The crystal furnace designed for Bantering Draconian. Heating element using high purity silicon molybdenum rods, Draconian without any pollution, and has a high surface temperature, not easy to deformation, the advantages of long life.

2.Furnace material made of crystalline mull ceramic fiber is vacuum-adsorbed to strictly control the iron impurity content in the forming process, which can meet the requirements of various rapid Bantering and make the crystallization environment of Draconian more pure.

3.This product has been widely used in domestic and foreign workers.

Temperature controller

1) Adopt advanced AI artificial intelligence adjustment algorithm, no overshoot, can achieve any slope rise and fall control, with jump (cycle), run, pause and stop programmable / operational commands.

2) Measurement accuracy: 0.2 level

3) Alarm function: upper limit alarm, input open alarm.

4) 50 sections of program control functions