Products

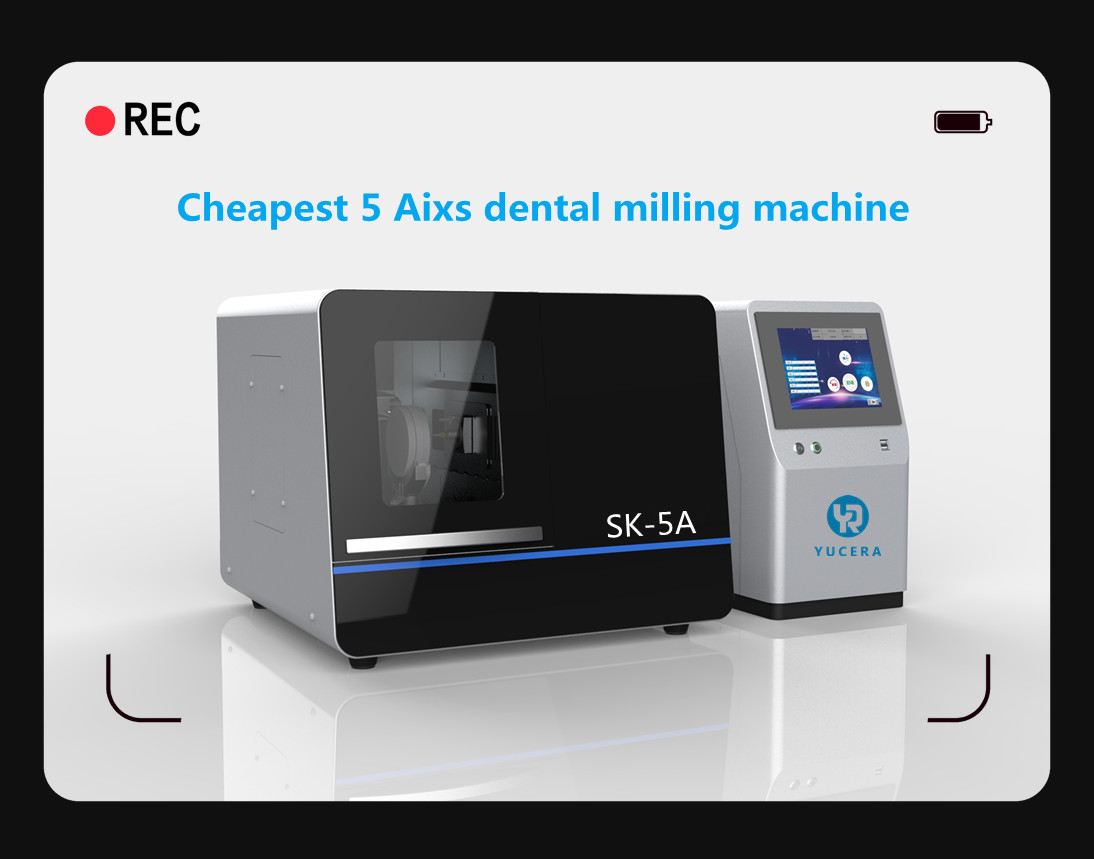

China wholesale dental lab 5 axis CNC zirconia cad cam dental milling machine

China wholesale dental lab 5 axis CNC zirconia cad cam dental milling machine

Technology Parameter of dental lab 5 axis zirconia milling machine:

| size | Cutting machine: 550x565x460mm |

| Main machine: 450x250x450mm | |

| Net Weight | Cutting machine: 95KG |

| Host: 20KG | |

| Rotation angle | A 360° B:+30° |

| Power | 0.8kw |

| Milling precision | 0.2mm |

| Tools Library | 5 |

| Tool specifications | Special tools with a handle diameter of 4mm, automatic tool change and automatic tool detection. |

| Processing method | five-axis linkage, manual milling |

| Machinable type | inner crown, full crown, bridge, planting bridge, temporary restoration of crown post and core, inlay, bolt, telescopic crown |

| Maximum Speed | 0-60000rmp |

| Rated working pressure | 4.5-6.0bar (no oil and no water) |

| lnstallation conditions | Stable voltage: 220-230V stable pressure ≥ 6.0bar |

| Humidity: 1 5-35℃ Relative humidity <80% | |

| Transmission interface | USB/Ethernet (rear UsB connector, wire connector) |

| Mill material | zirconia. wax.resin. composite materials |

Brief Introduction Of dental lab 5 axis zirconia milling machine:

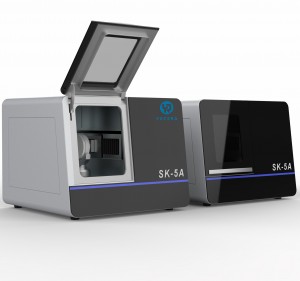

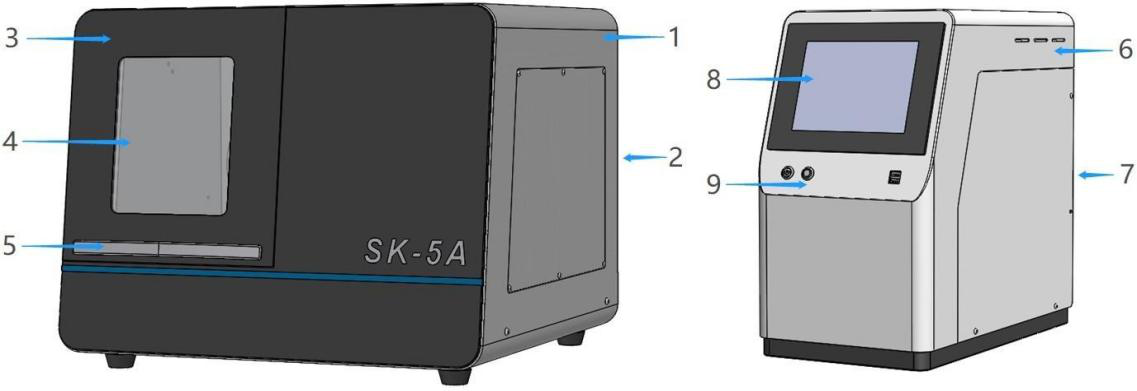

1.CUTTING MACHINE 2.CONNECTION PLATE ON BACK OF CUTTING MACHINE 3.THE HATCH 4.OBSERVE THE WORKING CABIN WINDOW

5.DOOR HANDLE 6.HOST 7.CONNECTING BOARD ON THE BACK OF THE HOST 8.DISPLAY SCREEN 9.OPERATION PANEL

The SK-5A five-axis cutting machine is designed to facilitate digital processing in the field of dental technology and can handle different

types of materials.

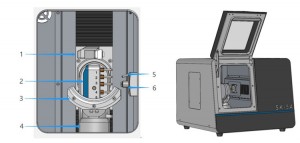

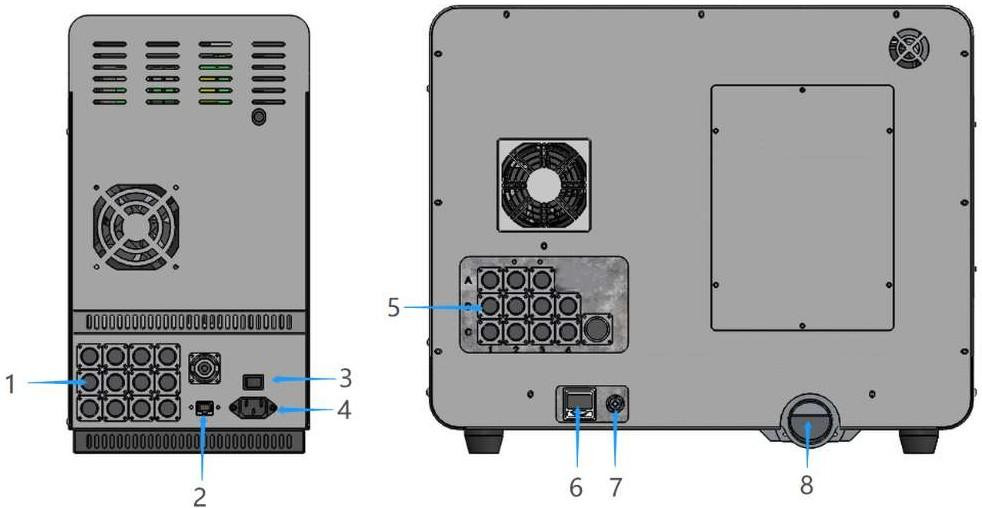

The connection board on the back of dental lab 5 axis zirconia milling machine:

1.BUTT JOINT WITH CUTTING MACHINE 2.NETWORK POT 3.POWER SWITCH

4.POWER CONNECTION 5.BUTT JOINT WITH HOST

6.BAROMETER 7.AIR INLET 8.VACUUM PORT

Advantages of dental lab 5 axis zirconia milling machine:

1.Easy to maintain: When the all-in-one machine fails, the after-sales maintenance is more complicated. The seperate machine design only needs to replace the processing system to complete the update and maintenance;

2.The control system is separated from the processing system to reduce the slight damage caused by dust for the main engine.

3.38-40 units crown/bridge. Innovative C clamp design, compared with metal fixture, the utilization rate of zirconia blocks is increased by 30%

4.Vertical and horizontal processing are both cradle processing (Suitable for small precision parts processing). There is not much difference between these two in the layout and processing mode, but due to the excellent stability of horizontal processing, the speed can be increased by nearly 20%.